10 Best Laser Engravings 2025 in the United States

Winner

LaserPecker LP4 Laser Engraver Ultimate Bundle with Air Purifier, Slide and Rotary Extension, Dual Laser Engraving and Cutting Machine for Metal, Wood, Acylic, Jewelry etc.

The LaserPecker LP4 Laser Engraver Ultimate Bundle is designed for high productivity and versatility, making it suitable for business purposes and creative work at home or in studios. It includes an air purifier, slide extension, and rotary extension, which enhance efficiency and cleanliness during batch processing. The air purifier boasts a 4-layer filtration system that achieves a 99.97% purification rate, ensuring a healthy workspace, while its compact and portable design caters to mobile DIY customers.

Most important from

168 reviews

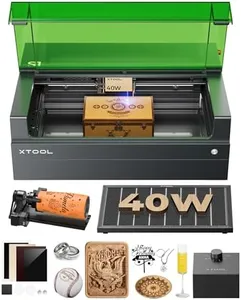

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

The xTool S1 40W Laser Cutter and Engraver is a powerful machine designed for versatility and high productivity. With its 40W laser power, it can cut through thick materials like 18mm cherry wood in a single pass and engrave at speeds up to 600mm/s. The large engraving area of 23.93" x 15.16" makes it suitable for big projects, such as door signs or multiple small items like dog tags at once. Its precision and resolution are enhanced by xTool’s Pin-point Positioning technology and the capability to handle curved surfaces and long projects using AutoPassthrough Technology.

Most important from

136 reviews

xTool F1 2-in-1 Dual Laser Engraver, Lightning Speed Portable Laser Engraving Machine, Ultra HD Fiber Laser Engraver for Jewelry, Metal, Wood, Leather

The xTool F1 2-in-1 Dual Laser Engraver stands out for its impressive speed and efficiency, capable of reaching up to 4000mm/s. This high speed makes it particularly suitable for batch-processing items like metal business cards and jewelry. The dual laser system is versatile, enabling it to work with over 300 materials, including metals, wood, acrylic, and even perform tasks like rust removal. The power levels are substantial, with a 2W infrared laser for metals and a 10W diode laser for materials like wood and acrylic, allowing for deep cutting and detailed engravings.

Most important from

269 reviews

Top 10 Best Laser Engravings 2025 in the United States

Winner

10.0 score

LaserPecker LP4 Laser Engraver Ultimate Bundle with Air Purifier, Slide and Rotary Extension, Dual Laser Engraving and Cutting Machine for Metal, Wood, Acylic, Jewelry etc.

LaserPecker LP4 Laser Engraver Ultimate Bundle with Air Purifier, Slide and Rotary Extension, Dual Laser Engraving and Cutting Machine for Metal, Wood, Acylic, Jewelry etc.

Chosen by 1209 this week

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

xTool F1 2-in-1 Dual Laser Engraver, Lightning Speed Portable Laser Engraving Machine, Ultra HD Fiber Laser Engraver for Jewelry, Metal, Wood, Leather

xTool F1 2-in-1 Dual Laser Engraver, Lightning Speed Portable Laser Engraving Machine, Ultra HD Fiber Laser Engraver for Jewelry, Metal, Wood, Leather

LaserPecker LP5 20W Fiber & Diode Dual Laser Engraver, 10X Faster 0.0027mm Precision for Metal/Wood/Jewelry, Portable 6kg Laser Cutter for Instant Store Customization, 3D Grayscale Engraving Machine

LaserPecker LP5 20W Fiber & Diode Dual Laser Engraver, 10X Faster 0.0027mm Precision for Metal/Wood/Jewelry, Portable 6kg Laser Cutter for Instant Store Customization, 3D Grayscale Engraving Machine

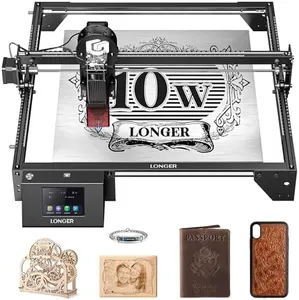

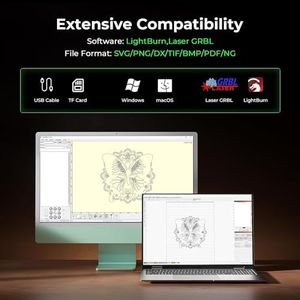

LONGER Laser Engraver Ray5 10W, 60W DIY Laser Cutter and Laser Engraving Machine with 3.5" Touch Screen,0.06mm Laser Spot 10000mm/min, Offline Usage CNC Laser Engravers for Wood Metal Acrylic Glass

LONGER Laser Engraver Ray5 10W, 60W DIY Laser Cutter and Laser Engraving Machine with 3.5" Touch Screen,0.06mm Laser Spot 10000mm/min, Offline Usage CNC Laser Engravers for Wood Metal Acrylic Glass

WECREAT Vision 20W Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Metal Wood Acrylic DIY Craft Gifts Making

WECREAT Vision 20W Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Metal Wood Acrylic DIY Craft Gifts Making

xTool P2 55W CO2 Laser Cutter, Smart Desktop CO2 Laser Engraver and Cutter Machine, Dual Smart 16MP Cameras, Curved Surface Engraving, Create with Wood and Metal Acrylic Glass Fabric Leather (White)

xTool P2 55W CO2 Laser Cutter, Smart Desktop CO2 Laser Engraver and Cutter Machine, Dual Smart 16MP Cameras, Curved Surface Engraving, Create with Wood and Metal Acrylic Glass Fabric Leather (White)

8.8 score

Creality Laser Engraver Enclosed, Falcon2 Pro 60W Output Laser Engraving Machine, 25000mm/min Speed Laser Cutter with Air Assist, Auto Fan, Camera Positioning for Wood and Metal

Creality Laser Engraver Enclosed, Falcon2 Pro 60W Output Laser Engraving Machine, 25000mm/min Speed Laser Cutter with Air Assist, Auto Fan, Camera Positioning for Wood and Metal

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.